An American company, AVADI, has created an innovative sort of rotary piston engine that is incredibly lightweight and could be suitable for a variety of applications.

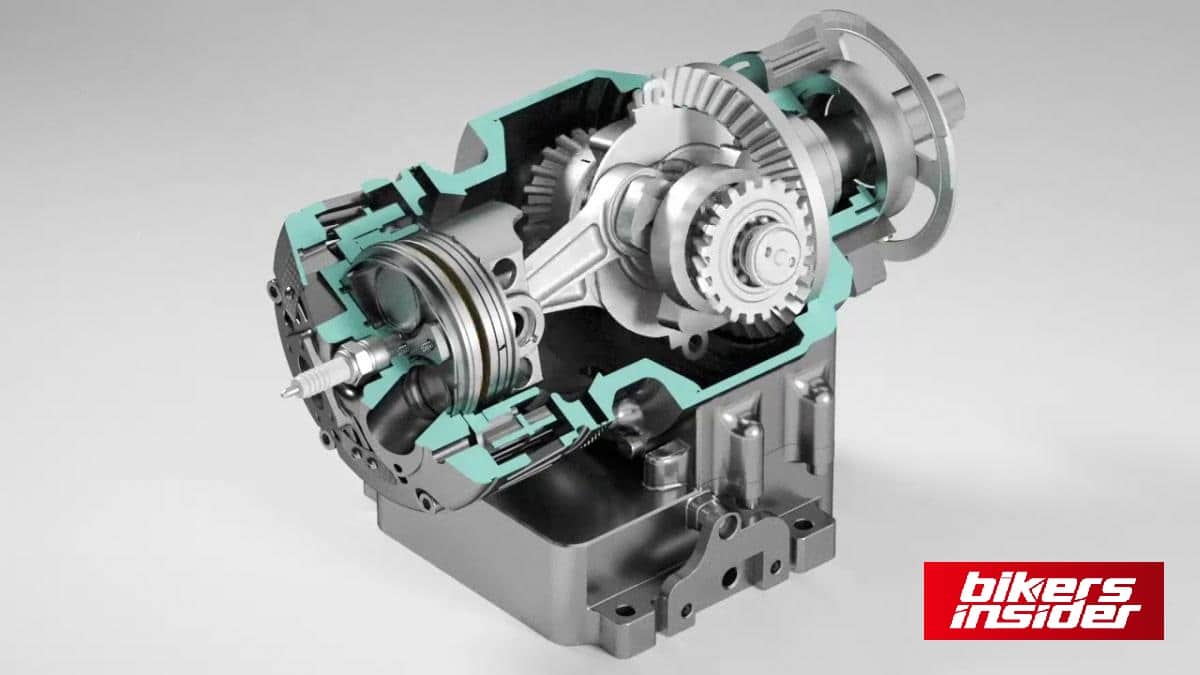

The rotary piston engine is a modest 250cc prototype with conrods, unlike a standard (if you can call it that) rotary engine. It has a single-cylinder design and two conrods. Avadi describes the engine’s design as a “single-cylinder with a self-centering rotating piston connected to a pair of counter-rotating, self-balancing connecting rods.” The connecting rods’ scissor-like action efficiently transfers the piston’s vertical stroke into rotational movement without a traditional crankshaft-based engine. This puts less side strain on the cylinder wall and reduces friction, heat, and wear.

Working principle

As the piston moves, the two rods travel in a scissor-like pattern, with each rod individually coupled to a pinion gear at the bottom end, which rotates on a fixed ring gear attached to the crankcase. The ring gear is the only non-rotating major mechanical component. The piston, cylinder, and connecting rods all rotate. These two connecting rods and their matching pinion gears are housed in what Avadi calls a ‘half shaft,’ which is effectively the housing where up-and-down piston motion is transformed into a rotating motion.

Aside from its innovative internals, the rotary piston engine’s compact dimensions and lightweight may be its most significant advantages. The entire engine weighs just 10.7kg, and even in the early phases of prototype manufacture, it produces 15bhp at 3,700rpm and 22.3 lb-ft at 3,500rpm. The Avadi’s low weight and compact form make it an appealing option in the power sports, ATV, and motorcycle markets. It’s also encouraging to note that, despite a continual (and, in some cases, forced) shift towards electrification, some people are still innovating in the internal combustion engine field.

For more news and updates, keep visiting BikersInsider.